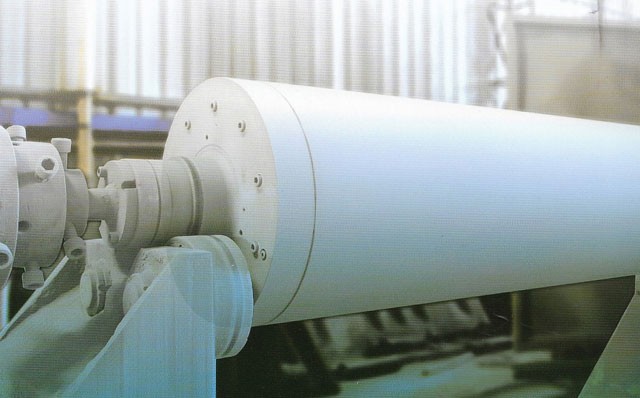

Roller conveyor is suitable for conveying items with a flat bottom. Loose materials, small items, or irregular items need to be placed on pallets or in turnover boxes for transportation. Capable of transporting single heavy materials or withstanding significant impact loads.

The roller conveyors are easy to connect and filter, and can be combined with multiple roller lines and other conveying equipment or specialized machines to form a complex logistics conveying system, completing various process requirements. The stacking and conveying of materials can be achieved by using a stacking drum. When designing a power drum conveyor line, the tensile strength of the chain should be considered, and the single line should not be too long; The structure of a roller conveyor mainly consists of a transmission drum, a frame, a bracket, a driving part, and other parts.

Roller material: mainly made of metal rollers (carbon steel and stainless steel).

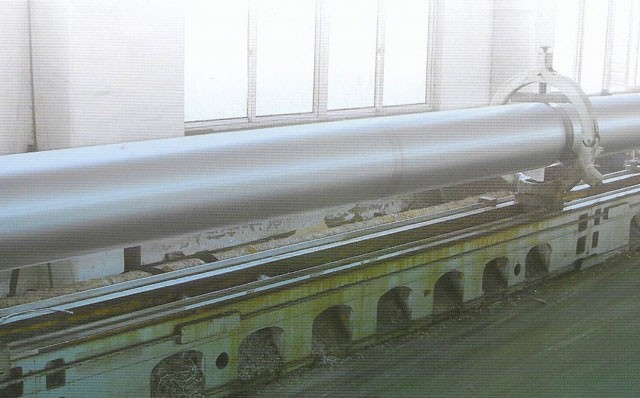

Driving methods: deceleration motor drive, electric drum drive;

Transmission methods: single chain wheel, double chain wheel, O-belt, flat friction transmission belt, multi wedge belt, etc;

Angle: 30 degrees -180 degrees; Roller conveyor has the characteristics of large conveying capacity, fast speed, light and fast operation, and can achieve multi variety co line diversion conveying.

Roller conveyor is suitable for continuous conveying, storage, sorting, packaging and other needs of various finished items, and is widely used in industries such as electromechanical, automotive, tractor, motorcycle, light industry, home appliances, chemical, food, postal and telecommunications.