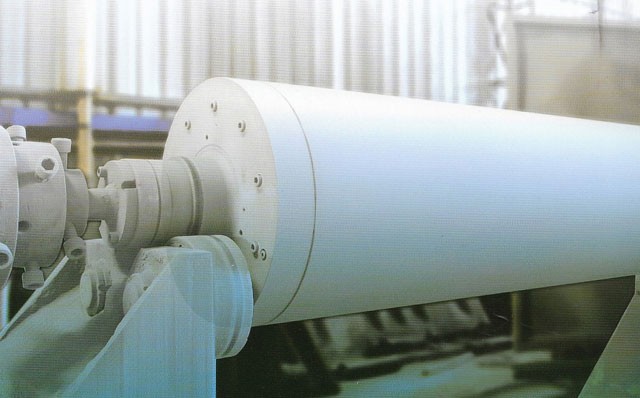

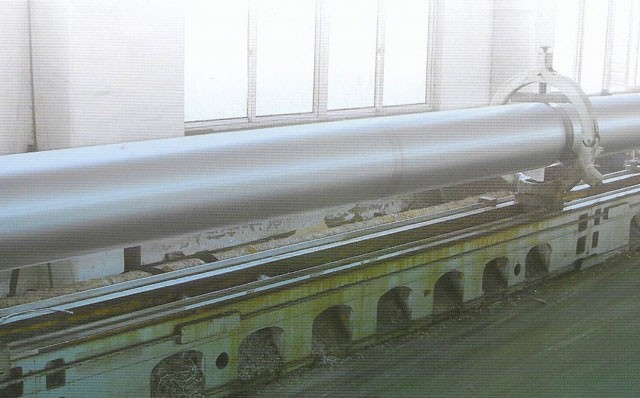

The rollers are usually made of seamless steel pipes, and depending on different process requirements, materials such as aluminum alloy 6061T5304L/316L stainless steel, 2205 duplex stainless steel, cast steel parts, and solid forged alloy steel cores may be used.

Roller production requirements:

1. The roller should have sufficient rigidity to ensure that under heavy loads, the bending deformation does not exceed the allowable value.

2. The surface of the roller should have sufficient hardness, generally requiring HRC50 degree or above, and have strong corrosion resistance. The coating has anti peeling ability, ensuring that the working surface of the roller has good wear resistance and corrosion resistance.

3. The working surface of the roller should be finely machined to ensure dimensional accuracy and surface roughness. The roughness should be above Ra0.16 and there should be no pores or grooves. The wall thickness of the working surface of the roller should be uniform, otherwise it will cause uneven temperature on the roller surface and affect the quality of the product.

4. The material of the roller should have good thermal conductivity, usually made of cold hard cast iron, and in special cases, cast steel or molybdenum chromium alloy steel can be used. Whether heated or cooled, it can achieve fast and uniform results.