Roller is widely used in various transmission and conveying systems and sorting conveying equipment, such as circular screen printing machines, digital printers, mining conveying equipment, papermaking, packaging machinery, etc. Introduction to Classification of Roller Specifications

Roller is widely used in various transmission and conveying systems and sorting conveying equipment, such as circular screen printing machines, digital printers, mining conveying equipment, papermaking, packaging machinery, etc.

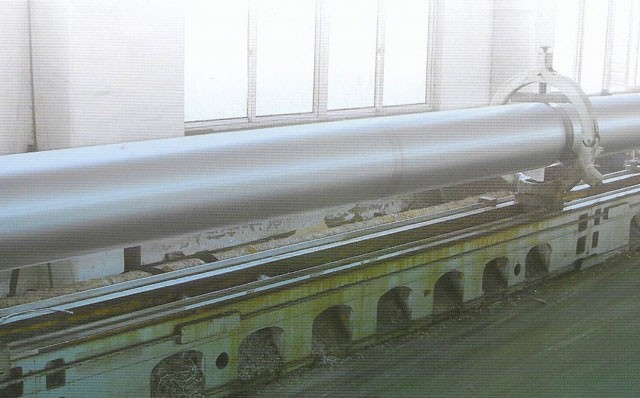

The roller is a cylindrical part, which is divided into driving roller and driven roller according to its purpose; According to the driving method, it is divided into power drum and unpowered drum. Power drum is further divided into single chain wheel drum, double chain wheel drum, single O-belt drum, and double O-belt drum; The unpowered drum is divided into inner tooth shaft drum and spring pressed drum. Divided into cylindrical drum and conical drum according to structural form.

Classification of rollers:

Roller diameter selection: 25mm, 32mm, 38mm, 42mm, 50mm, 57mm, 60mm, 76mm, 80mm, 89mm. Roller material selection: carbon steel galvanized, carbon steel chrome plated, carbon steel coated with glue, aluminum alloy, stainless steel, ABS, etc. Roller type selection: unpowered roller, single chain roller, double chain roller, "O" belt roller, conical roller, groove roller. Roller fixing methods: spring pressing type, inner tooth shaft type, full flat tenon type, through shaft pin hole type.

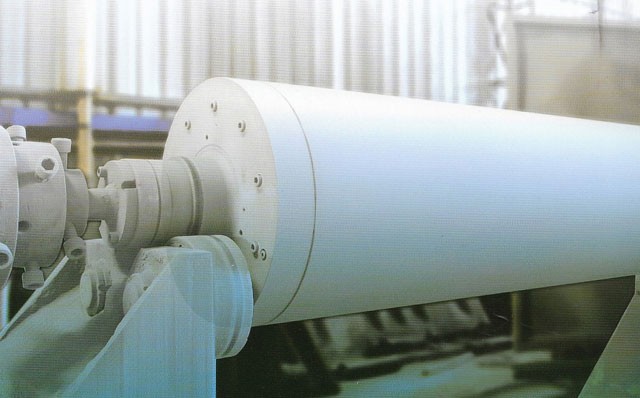

According to the process flow, it is divided into: rolling rod, smoothing rod, casting roller, etc;

Classified by functional use: heating roller, cooling roller, guide roller, support roller, etc. Classified by structure: seamless steel pipe roller, forging and centrifugal casting roller, etc.