The processing technology types of mirror rollers

1、 Component welding:

Assemble and weld the inner plate, shaft head, liner, plug plate, inner tube, etc. The inner tube is statically balanced within 50g, and the inner tube is marked with a rotation line. Weld the flat steel flow channel.

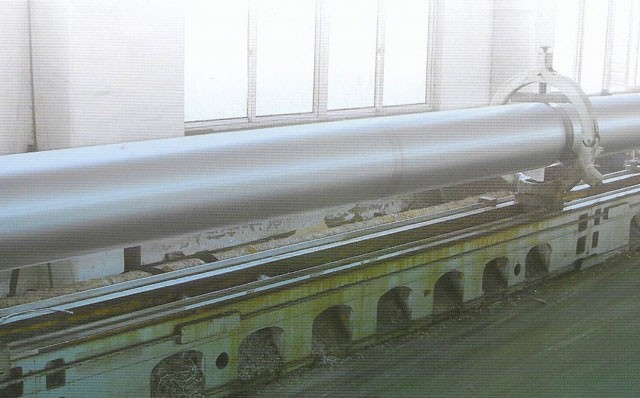

2、 Vehicle configuration, installation, and welding:

Install the inner pipe of the vehicle, with a size interference of 0.4mm with the outer pipe. The angle of the two plate fillet welds is 15X30 degrees. Polish the inner pipe, clean the slag, and inspect whether the inner pipe size matches the inner diameter size of the outer pipe. Heat the sleeve in place and weld it as a whole after cooling and shrinking. (Note: 45 # steel is heated before welding and insulated after welding)

3、 Annealing, rough turning, quenching:

Heat treatment for annealing, process quenching and tempering, multiple stress relief, allowance for rough turning, static balance, if it exceeds 50g, it is necessary to calculate the deviation amount and borrow the car from the bed.

Quenching: The surface hardness requirement is HRC58 ° -60 °, and there are no turtle cracks on the roller surface.

4、 Fine turning and rough grinding:

Trim the pinholes on the top of the two shaft heads, and the runout between the two shaft heads and the roller surface is less than 0.05. Machine the length to size according to the drawing requirements, with an outer circle allowance of 0.5-0.6. Grind the support circle into the bracket position, and grind the roller surface size according to the requirements in the diagram. The runout of the roller surface between the two Ra0.5 axis heads is less than 0.02.

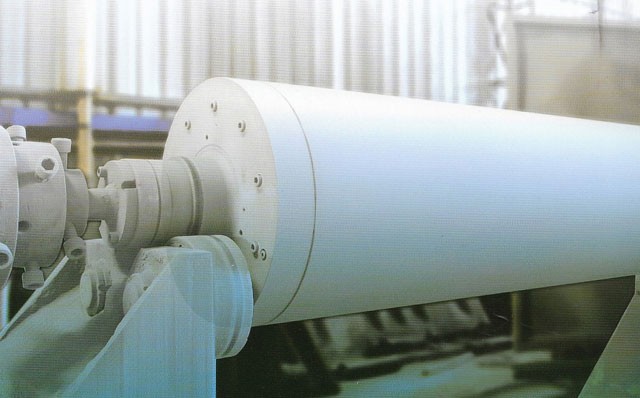

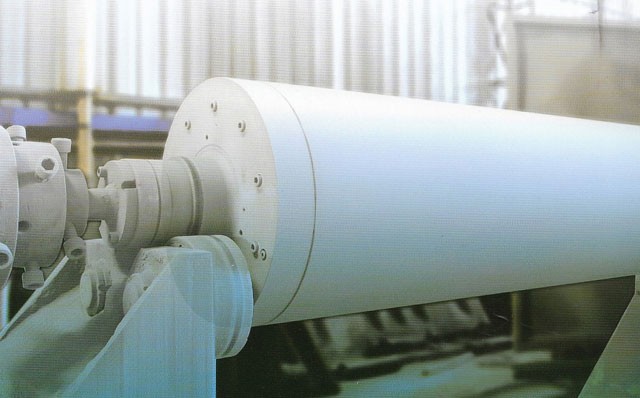

5、 Dynamic balancing, electroplating, and precision grinding:

Perform dynamic balance G40 level, seal the air vent, conduct pressure test without leakage, and conduct water pressure unobstructed test. Electroplated hard chromium, with a uniform 0.15 chromium layer on one side without defects such as pinholes or peeling. Fine grind the two shaft heads, and ensure that the runout of the roller surfaces between the two bearing blocks is less than 0.01, with a roughness of 0.8. Grind all gears of the remaining shaft heads to the tolerance range.

6、 Frosted and finely polished mirror surface:

Use a disc grinder to sand the roller surface and inspect it for any defects such as water ripples, spiral marks, pinholes, and fly debris. On the polishing machine, polish the roller surface to a roughness of Ra0.01-0.005 (with a smoothness of 14 levels) to achieve a super mirror finish. After chrome plating and polishing, the hardness is HRC62 °.